AP Automation for manufacturing: Streamline invoice processing

She sought feedback from other users and compared it against other available solutions. Emily was particularly impressed with A/P One’s user-friendly interface and its ability to integrate seamlessly with their existing ERP system. Intrigued by its potential, she delved deeper into understanding its features and capabilities.

Our platform

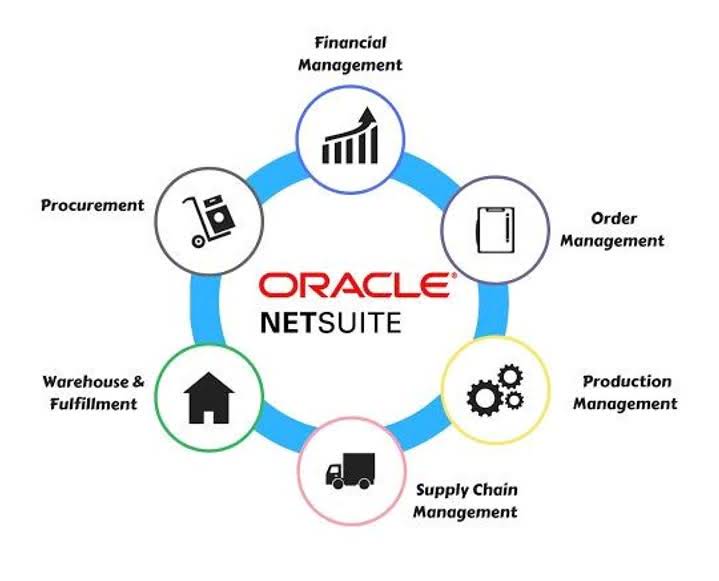

When AP resides outside the ERP, latency and order changes lead to distortions between systems over time. Instead of introducing yet another disconnected system, AP automation platforms integrate natively with major manufacturing ERPs like SAP, Oracle, Infor and Microsoft Dynamics. Standard interfaces eliminate complex custom coding needs during implementation projects. As manufacturing becomes faster, leaner and more complex, AP’s financial optimization role will only grow.

Accelerate Invoice Cycle Times and Improve Cash Flow

- This method, known as three-way PO matching, allows you to match invoices and supporting documents, such as purchase orders and shipping receipts.

- Traditional AR processes require staff to track due dates manually, send payment reminders, apply payments to invoices, handle payment discrepancies, and manage collection efforts.

- In an industry where production speed and supplier trust matter most, automation is no longer optional.

- Manual accounts payable processes are notoriously time-consuming, costly, and error-prone.

- Melio offers a flexible payment method for invoices, allowing customers to pay with a card (with a 2.9% fee) or ACH bank transfer for free.

- You can choose your template from multiple options like Accounts Payable, CRM, HR, Customer support etc. for the process you want to automate.

Manufacturing companies are unique when it comes to accounts payable and require flexible software that adapts to their processes and workflows to ensure control over their supply chain. Whether you’re processing hundreds or even thousands of supplier invoices, AP Automation is the gold standard for streamlining processes. AP automation in manufacturing refers to the use of digital tools and software to automate the full accounts payable process — from invoice capture and validation to approval and payment. Manufacturing companies often deal with a high volume of vendor invoices, complex approval hierarchies, and tight alignment between financial systems and production timelines. Manual AP processes can slow down procurement, introduce errors, and strain supplier relationships. Airbase is an all-in-one spend management platform designed to unify and streamline accounts payable, employee expense management, and corporate card spending.

Why automate your manufacturing AP workflow?

Automation software helps to improve efficiency in billing and paying processes for businesses by reducing manual data entry tasks that are time-consuming and prone to unearned revenue errors. AP automation software digitizes and streamlines the entire accounts payable process. AP automation software can reduce these costs while cutting processing time from days to hours. These solutions use optical character recognition (OCR), automated workflows, and intelligent payment processes to automate everything from invoice capture to vendor payments. AP automation software replaces manual, paper-based accounts payable tasks with streamlined digital workflows. Automating AP processes can help manufacturing companies take advantage of early payment discounts by ensuring invoices are processed and approved quickly.

Best for High-Volume Global Payments

The latest statement of financial condition for Brex Treasury LLC is available here. Aim for a 30-to-60-day pilot phase to process multiple invoice cycles, and include tech-savvy early adopters and skeptics who represent typical users. Their combined feedback will help you address concerns and refine training materials for the wider implementation. Supplier relationships, freelancer agreements, legal partnerships—these formal agreements are… Schedule a demo with an onPhase automation expert today and keep your operations moving, no matter what. Additionally, this article provides a detailed roadmap for implementing AP Automation in your organization, supported by real-world success stories that showcase its practical impact.

This can lead to significant cost savings and improved supplier relationships. Tracking and managing early payment discounts through automation enhances cash flow management and financial planning. As a manufacturer, disjointed accounts payable processes can strain working capital and hide excessive expenditures across facilities. But with Medius AP automation, you can optimize invoice processing, compliance, and cost controls to drive margins.

AP automation success stories from manufacturing companies

- Manual AP processes can slow down procurement, introduce errors, and strain supplier relationships.

- Long approval workflows can give you more than just a headache — they can also have a negative impact your bottom line.

- The reduction in processing time means vendors are paid more promptly, improving supplier relationships and often securing better terms and discounts.

- It replaces manual accounts payable department tasks and provides paperless document management for payables.

- Kanverse AI can handle various accounts payable automation tasks, including processing invoices, PO matching, payment requests, and more, without the need for templates.

- Since then, the finance team has saved hours each week on AP processing and gained real-time visibility into company-wide spend—all from a single, easy-to-use system.

Switching from manual to automated AP processing can quickly improve your entire accounts payable process. Implementation timelines generally range from a few weeks to several months, varying based on several factors. While daily operations of modern cloud-based AP solutions usually don’t require IT support due to user-friendly QuickBooks ProAdvisor design and vendor assistance, IT involvement is typically crucial during implementation. Their expertise is often needed for setting up and troubleshooting the ERP integration, configuring security aspects like Single Sign-On, and ensuring network compatibility. After setup, finance and AP teams can generally manage the system independently. And when AP automation is integrated with ERP systems, the benefits go even further.

In manufacturing, procurement specialists are critical in ensuring the continuous flow of materials that keeps the production line moving. Their job is crucial for maintaining production schedules and meeting customer demand. However, when these specialists are bogged down by slow invoice approvals and manual reconciliation, the entire production process can be jeopardized. Delays in processing invoices can lead to delays in receiving materials, which can halt production and impact delivery schedules. Now, picture a world where these cumbersome tasks are seamlessly automated, making manufacturing ap automation your financial operations not only more efficient but also more reliable.